Coal for Electric Power Production in the USA

Michel LUNG

This is a summary of two articles by John McPhee published in the issues of 5 and 10 October 2005 of the New Yorker, dealing with a little known aspect of the demands on coal transport for the production of electric power in the United States. In the second part of this text, we will consider some of the environmental and economic issues related to this use of coal.

The “Clean Air Act” of 1970 requires that American industry reduce the sulfur content of gases released to the atmosphere by large facilities, in particular by coal-burning electric power plants. Many power plants had been built near coal beds whose sulfur content is now considered unacceptable. Thus, either the power plants had to be fitted with expensive and cumbersome devices to capture the SO2 in the smoke before it is released to the atmosphere or they had to burn coal with low sulfur content such as that found in the huge coal beds of northern Wyoming.

As an example, the coal in Pennsylvania has very high calorific power and it lies in two meter thick layers but its sulfur content is large while in Wyoming, in the “Fort Union Formation, Powder River Basin”, the layers are 30 meters thick, they lie 30 meters below ground, the coal has five times less sulfur but 30 % less calorific power.

Thus, for the past 20 years, the power plants have been burning coal from the Powder River Basin in Wyoming with its Orin Line, a short three track railroad with multiple ramifications which handles 23 000 coal trains per year. It is the world’s largest coal extraction facility. Today, the excavations are 60 meters deep and 3 to 5 km long. The mine can be worked over the next 50 years at the present depth with no problem and the reserves are estimated at 200 years at the present extraction rate.

Everyday, 65 coal trains carrying 15 000 to 21 000 metric tons of coal (their total end to end length would reach 160 km) leave the mine-head which accommodates several facilities. A typical train comprises 135 aluminum hopper cars, each containing 120 metric tons of ore. Its weight is approximately 2 700 metric tons when empty and 18 000 metric tons when loaded. It is 2 700 meters long (beware at railroad crossings!). These trains are pulled by 3 to 5 diesel-electric (usually alternating current) engines with 13 000 horse-power each. They are placed at the head, in the middle and at the end of the train, they are interconnected electronically and communicate with the track and with the traffic regulating centers which are often far away.

The conveying crews usually comprise a fireman and a mechanic. Each crew covers a portion of the journey, always the same one, and works 12 hours, not a minute longer. Since unpredictable events always occur, the train often stops in the middle of nowhere so that a pickup service has to bring in the new crew and bring back the crew coming off duty. In poor weather conditions, e.g. snow storms, this is not a minor undertaking. A head wind can slow a train down by up to 20 km/h in spite of the powerful engines.

The author takes us to Plant Scherer in Georgia on a 17 000 metric ton train. Plant Scherer is the largest coal fueled power plant in the USA, it belongs to “Georgia Power”. The power plant has 4 in-line turbo generators extending over 450 meters for a total power output approaching 3 000 MW. Under normal conditions, the nearly 3 000 km long journey is accomplished within 5 days. If the trip lasts more than an agreed amount of time, the Norfolk Southern Line has to pay Georgia Power a compensation. A daily average of three and a half trains make the journey from Wyoming; this means an annual 1300 trains with 11 million metric tons of coal conveyed per year.

Train loading and unloading at each end of the line produces enormous amounts of coal-dust which is normally pulled down by means of water spraying, except in freezing weather. As a matter of fact, coal-dust accumulation is liable to make a train derail. At Plant Scherer, the train travels along a wide 2 km diameter loop. At the center of the loop there is a 1 million metric ton buffer coal reserve. The train moves at 5 km/h above hoppers and, within 3 to 4 seconds, each car is emptied from the bottom, which opens up. In the most favorable conditions, the train is emptied within ½ hour. If train unloading takes more than 4 hours, Georgia Power has to pay a compensation to the carrier. The coal is crushed, pulverized and burned at a temperature not exceeding 1650° C to avoid the formation of nitrogen oxides, NOx.

The contents of a « typical » train is burned in less than 8 hours. Information is not provided on what is done with the solid ashes, nor toxic aerosols, nor on how much radon is released during the process.

The author interviews Damon Woodson, a mechanical engineer who has worked in nuclear power in the past and who says that “he had to come here to understand the usefulness of nuclear energy. A single truck of uranium ore can produce as much energy as this one million metric ton pile of coal. The way to go is nuclear if you want to have power.” He goes on to quote the following costs for the production of one million BTUs (British thermal units, 1BTU=1055 Joules=0,293 W-h) of heat.

-

With oil : $ 9

-

With gas : $ 6

-

With coal : $ 1.85

-

With nuclear : $ 0.5

Undoubtedly, this story will have an impact on the readers of the New Yorker who are numerous worldwide.

Moral of the Story

An attempt at drawing some environmental and economic conclusions from this story told in very lively terms is worthwhile.

In the US, 52 % of the electricity is produced in 500 coal-fueled power plants.

Because of environmental considerations, producers of electricity are fetching from afar an approximate 400 million metric tons of lower quality lower sulfur content coal, in spite of the additional conveying cost.

Wyoming coal alone represents almost half of the approximately 900 million metric tons of coal consumed in America. This consumption rejects an estimated 1.9 billion metric tons of CO2 (i.e. 8 % of the 25 billion metric tons of CO2 released to the atmosphere worldwide), 5 to 7 million metric tons of SO2 and 1.6 million metric tons of NOx. Replacing the coal by natural gas would almost halve these amounts but such a conversion to gas-fueled plants is becoming unlikely today because of costs.

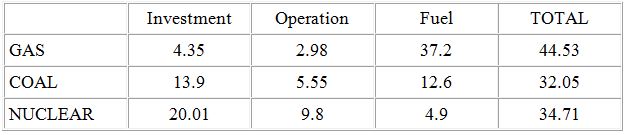

In the USA, the price of natural gas was $2 per million BTU in 2002, while it is $6 today. The costs quoted by the author of the article include only the fuel costs, they do not take into account the operation nor the amortization costs. Converting the above costs to dollars per electric MWh produced with the various fuels and assuming today’s best thermodynamic efficiencies (and this is not the case with a number of older power plants in the USA), i.e. 55 % for oil and natural gas, 50 % for coal and 35 % for nuclear fission, one obtains:

-

Oil: $ 55.8/MWhe

-

Gas: $ 37.2/MWhe

-

Coal: $ 12.6/MWhe

-

Nuclear: $ 4.9/MWhe

If the total costs are considered, the following approximate values are obtained, for the United States, in $/MWhe:

As shown in the table, the cost of nuclear power is close to that of coal power and, if servitudes such as ash removal, CO2 capture & storage or probable future taxes on carbon emissions are taken into account, nuclear power will end up less expensive. This holds true even if the price of uranium increases somewhat since its impact on the cost of a KWhe produced is very small (5 to 10 %).

For long distance transportation such as the one that brings the coal to Plant Scherer, the cost of the fuel used to pull the trains in the round trip journey is far from minor since some 10 % of the energy brought to the plant is spent for the conveying. With an oil barrel priced at $ 50, this can add as much as $ 10/MWhe to the production cost of electricity with coal.

If the environmental cost due to CO2 released to the atmosphere is counted in, the cost increases still more for coal power.

Assuming relatively low quality coal, we will consider an average of 1.2 metric tons of CO2 released to the atmosphere per MWhe produced.

The “Kyoto” tax could amount to $ 25/t (P. Criqui, CNRS, 26/9/05).

If the CO2 released by the power plant itself is to be captured and stored (excluding other CO2 released in the process, e.g. during transportation) and under the condition that the technical means are available, and also that appropriate reservoirs are on hand close by, today’s estimated cost per metric ton of CO2 is $ 50 to $ 100 which could decrease to $ 25 in the future (A. Rojey, IFP, 26/9/05).

CO2 capture and storage, then, would add about $ 30 per MWhe to the cost of electricity produced with coal, making this means of production still less advantageous as compared to nuclear power.

On the other hand, the conversion costs of the energy and transportation industries must be taken into account as well as public opinion which sees nuclear power as dangerous and laden with risks of proliferation; without voluntary action on the part of the Federal Government, it is likely that another few years will go by before the state of the matter changes significantly in the United States.

The reticence of these heavy industries to subscribe to the Kyoto agreement is understandable, all the more so since it seems that constraints are taken more seriously in the USA than in our European countries where the Kyoto targets are too often seen as mere recommendations.

CO2 capture devices are expensive, especially in the case of older plants, CO2 storage is far from being proven and its cost, in all events, is far from negligible even if such storage can help retrieve gas, oil or methane marginally. Coal gasification plants will cost as much as nuclear power plants and the price of coal will have to be added in. The coal industry and the American electricity operators are thus at a cross roads and are about to face hard choices.

It will be interesting to watch how the situation evolves, probably slowly, with an increasing electricity sales price compensating, in an initial stage, the increasing production costs. If these were to increase by 25 to 30 % the industry could switch to gas, provided the gas is available. This possibility should be considered for Europe, in particular in Germany and perhaps Poland, as long as Russia supplies the gas.

______________

- Procès Verbal de la deuxième Assemblée Générale Extraordinaire du 13 avril 2013

- Les candidats à l'élection présidentielle et l'EPR.

- "Energie : Attention, virage dangereux !" - La Commission Européenne à l'épreuve de la clarté

- "Energie : Attention, virage dangereux !" - La RT2012 à l’épreuve du climat

- "Green" jobs: the end of false hopes

- "La France a besoin de scientifiques et de techniciens"

- "Le nuage de Tchernobyl se serait arrêté aux frontières" - Pierre SCHMITT

- "Save the climate" sent a letter to President Trump

- "Sortir du Nucléaire" au secours d’EDF

- “Futurs énergétiques 2050” (Energy futures for 2050)

- « EDF : l'Etat va rembourser près de 5 milliards d'euros au groupe sur 6 ans ! »

- « LE GAZ DE SCHISTE » une aubaine pour la France

- « Sauvons le Climat » acteur du débat sur la transition énergétique, autour d’un nouveau Président

- « Sauvons le Climat » décline ses « 15 propositions du Débat national sur la transition énergétique »

- « Sortir du Nucléaire » n'a pas tout faux, pour une fois. Ni tout juste !

- « Sortir du Nucléaire »crie haro sur les députés « radioactifs »

- * Lettre ouverte au président de la Commission Européenne

- 10 questions à Gilbert Ruelle sur l'éolien, une énergie du XXIème siècle ?

- 10 questions à Jacques Lesourne sur les relations entre la technologie, la croissance et l’emploi

- 10 questions à Jean Dhers sur le stockage de l’énergie électrique

- 10 questions sur l'avenir du charbon

- 10 questions sur l’hydrogène

- 10 questions sur les déchets nucléaires

- 19 réacteurs électronucléaires à l’arrêt

- 1ère Annonce Université d'été SLC 2015

- 1ère Annonce Université d'été SLC 2016

- 1ère Ecole d'été SLC - Cabourg - Septembre 2008

- 2 économistes face aux enjeux climatiques

- 2 économistes face aux enjeux climatiques

- 2009 Autrans : Electricité solaire ; Agriculture et climat

- 2010 Dijon : L’océan dans la problématique climat-énergie ;. Politiques urbaines

- 2011 Paris : Quel modèle énergétique pour l’Europe en 2030.

- 2012 Landéda : biomasse, chauffage, stockage de l'énergie, réseaux

- 2013 : Aix en Provence, Energie et Santé : Interviews

- 2014 Bordeaux : Le devenir du climat, pourquoi agir ?

- 2015 Paris : URGENCE CLIMATIQUE : quels objectifs pour la COP21 ?

- 2016 Le Creusot : Quel avenir pour le nucléaire au lendemain de l'accord de Paris ?

- 2024 Olympic Games

- 2ème Annonce Université d'été SLC 2015

- 46 associations call on Ursula Von der Leyen to include nuclear power in the European taxonomy

- 5 minutes pour la planète bis

- 6ème Université d'été SLC - Aix en Provence - 12 au 14 septembre 2013

- 9ème Université d'été de Sauvons Le Climat

- A Bruxelles, les Entretiens Européens (ASCPE) marquent des points !

- A Cherbourg les antinucléaires ont trahi l’écologie et le climat

- A petites doses

- A Political Decision: The Early Shutdown of the Fessenheim Nuclear Power Plant ... an Approach à la Gribouille

- A propos d’un débat caricatural sur la chaîne Arte : « Centrales nucléaires, démantèlement impossible »

- A propos de la décision du Conseil Constitutionnel sur la « taxe carbone »

- A propos de la déclaration de Martine Aubry sur la Sortie du Nucléaire

- A propos des 5 minutes de répit pour la planète

- A propos des gaz de schiste

- A propos du communiqué de la Maison Blanche sur la contribution essentielle du nucléaire

- About us

- Académie des Sciences

- Accident de Fukushima Dai Ichi

- Accident de Fukushima Dai Ichi (suite)

- Accidents nucléaires à la centrale de Fukushima Dai-ichi : Historique, évènements et conséquences

- According to German Greens: “Wind Turbines in Europe do Nothing for Emissions-Reduction Goals »

- ADEME : un scénario énergétique peu crédible

- Affaire Pellerin : Communiqué de la SFEN

- Agnès Pannier-Runacher: At last, a Minister of Energy to whom we can say Thank You!

- Agrément SLC

- Ah ! Le Joly pacte pour l’emploi !

- Air pollution and climate : The unexpected testimony of methane

- Alerte : la fonte accélérée de la banquise arctique témoigne de l'urgence d'agir pour le climat

- Allemagne : c’est en 2020 qu’on pourra juger de la meilleure stratégie pour « Sauver le Climat »

- Allemagne : données sur la production électrique photovoltaïque

- Allemagne : un montant record payé pour l’électricité verte en 2012

- Améliorer l’efficacité énergétique en utilisant la cogénération dans la production d’électricité

- Analyse et commentaires concernant le rapport de l'ADEME : Vers un mix électrique 100 % renouvelable en 2050

- Analyse comparative 2007-2009

- Analyse critique de la proposition de réduire la part du nucléaire à 50% du mix électrique en 2025

- Analyse critique de la proposition socialiste de réduire la part du nucléaire à 50% du mix électrique en 2025

- Analyse d’un retour d’expérience sur l’éolien allemand

- Analyse du pacte électrique breton

- Analyse du projet d’arrêté relatif aux énergies renouvelables électrogènes

- Analyse du scénario Negawatt 2006

- Analyse du scénario Négawatt 2011

- Analyse du scénario Négawatt version 2011

- Analyse économique critique du programme éolien

- Analyses de la production électrique

- Anthelme Triboulet recherche des financements

- Anything but numbers is open for discussion

- Appel aux candidats à l'élection présidentielle à propos du réchauffement climatique

- Appel aux candidats à l'élection présidentielle en faveur d'un grand absent: Le problème du réchauffement climatique

- Appel des États insulaires du Pacifique

- Appel mondial d’Académies des Sciences

- Approche allemande du facteur 4

- Approche expérimentale du réchauffement climatique

- Après Copenhague

- Après Copenhague : méfions nous des faux prophètes et des illusionnistes !

- Après Doha ?

- Après Fukushima les médias aussi pourraient faire leur examen de conscience

- Après le pétrole...Nucléaire ou Charbon ?

- Argumentons face aux « climato-sceptiques »

- Arrêt de Fessenheim dans des conditions responsables ?

- Arrêt des réacteurs EDF et le climat

- Arrêtez de mentir !

- Arrêtons de chauffer: Pourquoi un réchauffement de 4°C doit être évité

- Article of the Nobel prizes, sponsors of SLC

- Aspects financiers du scénario Negatep

- Assemblée générale 2016

- Association des Ecologistes pour le Nucléaire

- Association des Retraités du Groupe C.E.A.

- Associations Partenaires de Sauvons le climat

- Au delà de Kyoto

- Au sujet de "LA VERITE SUR LE NUCLEAIRE Le choix interdit" de Corinne Lepage

- Audition de « Sauvons Le Climat » au Sénat le 25-11-2014

- Augmentation des quotas d'émission de CO2 par EDF

- Aurons-nous de l’énergie pour demain ?

- Australia: Has the War Against Climate Change Begun?

- Avantages et inconvénients pour la santé de la biomasse - Biomasse et Santé

- Avantages et risques comparés pour la santé des différentes sources d'énergie

- Avec le nucléaire – un choix réfléchi et responsable

- Avis de la CNE2 sur la gestion des matières et déchets radioactifs

- Avis sur la proposition par l'OPECST d'instauration, pour l'exploitation des bâtiments

- Bali: ils pouvaient mieux faire

- Bar des Sciences - Béthoncourt - 7 avril 2011

- Belgique : données sur la production électrique éolienne

- Benjamin Dessus, refaites vos calculs

- Best Wishes SLC 2021

- Bilan 2005 et voeux 2006

- Biocarburants et gaz à effet de serre

- Biodiversité et dérèglement climatique - Dijon - 9 décembre 2010

- Biodiversité et dérèglements climatiques

- Board of directors

- Bretagne : Analyse graphique mensuelle par filières de la production électrique (données eCO2mix)

- Bulle Photovoltaïque

- Cahier d’acteur sur le projet PENLY 3

- Cahier de participation déposé par Sauvons Le Climat pour la Commisson Nationale sur la Transition Energétique (CNDTE)

- Cahiers de participation SLC Dauphiné Savoie : logement et chauffge bois, transition allemande, hydraulique

- Can El Hierro be 100 % electric-renewable?

- Can photovoltaics replace nuclear power?

- Cancùn : le climat attendra-t-il ?

- Canicule en France et production électrique

- Captage et stockage du CO2 - Elisabeth HUFFER

- Captage et stockage du gaz carbonique (CSC)

- Capture et séquestration du CO2

- Carbon Neutrality - What Are We Talking About?

- Carbon Neutrality - What Are We Talking About?

- Carbon Neutrality: Yes, but How?

- Cellules photovoltaïques - fiche développement

- Cellules photovoltaïques - fiche présentation

- Chaleur renouvelable, Conseil d’Etat et modalités d'application de la RT 2012

- Châlons, 30 mai 2013, conférence : débat sur la transition énergétique

- Changement climatique : le certain, le probable, le possible et l’inconnu

- Charbon, les métamorphoses d’une industrie

- Chauffage bois - fiche n°1

- Chauffage solaire - fiche n°1

- Chauffage solaire - fiche n°2

- Cher Nicolas Hulot

- Chiffrage du projet de mise à l’arrêt de 24 réacteurs nucléaires sur 58 d’ici 2025 et de réduction de 75 à 50% de la production d’électricité nucléaire en France - Jean-Pierre PERVES

- Chronique de Doha (numéro 3)

- Cinq mois avant la COP21, Barack Obama dévoile son plan climat

- Classement 2010 des ONG par Prometheus

- CLI de Gravelines - Point sur la 3ème visite décennale du réacteur n°1

- Climat une planète et des hommes. Quelle influence humaine sur le changement climatique

- Climat - Energie : Eviter la surchauffe

- Climat : 22 contre-vérités qui exaspèrent …

- Climat : l'objectif des 2°C appartient, hélas, au passé !

- Climat : le vrai et le faux

- Climat : Oser le nucléaire !

- Climat d’hier à demain

- Climat et gaz à effet de serre

- Climat et Société : Climats passés, passage de l’homme, climat futur : repères essentiels

- Climat, énergie et santé : 6ème Université d'été SLC - 12 au 14 septembre 2013

- Climate-energy: what do presidential candidates promise?

- Climate: Recognizing True from False

- Closing of Fessenheim: letter from Sauvons Le Climat to Bernard Cazeneuve

- CO2 emissions from fuel combustion : Highlights 1971-2002

- Coal for Electric Power Production in the USA

- Colloque : Une journée pour le climat (Dijon, 20 avril 2015)

- Colloque "A la recherche de la voiture propre" avec Confrontations Europe

- Colloque "Energies et Effet de Serre" - Paris - 10 octobre 2007

- Colloque « A la recherche de la voiture propre »

- Colloque Energies décarbonées - Grenoble - 2006

- Colloque G.R.R.T : Nucléaire et communication, vrais et faux experts - 6 juin 2013, Paris

- Colloque SLC - Confrontations Europe - Bruxelles - 7 octobre 2008

- Combien de CO2 ?

- Combien l’éolien va-t-il nous coûter ?

- Comment améliorer l'efficacité de la filière nucléaire française

- Comment compter et évaluer les différentes énergies, et en particulier les énergies renouvelables : réflexions méthodologiques et exemples

- Comment EDF relance nos émissions de CO2

- Comment en un plomb vil, l’or pur s’est-il changé ? - Pierre DELAPORTE

- Comment faire face à l'urgence climatique ?

- Comment faire face à la disparition annoncée du pétrole ? - Jean LEROY

- Comment fonctionne le GIEC ? - Jean POITOU

- Comment le Japon a répondu à l'arrêt des réacteurs nucléaires suite à l'accident de Fukushima

- Comment le Japon a répondu à l'arrêt des réacteurs nucléaires suite à l'accident de Fukushima (révision 08-2015)

- Comment le réseau électrique français a géré un mois d’hiver somme toute « normal » en janvier 2017

- Comment les énergies renouvelables, remplaçant des centrales nucléaires, détruisent des emplois

- Commentaire du projet de Directive Européenne sur les Energies Renouvelables

- Commentaires sur "L’Homme est-il responsable du réchauffement climatique ?"

- Commentaires sur l'article de Henri Atlan paru dans le Monde du 28-29 mars 2010

- Commentaires sur la RT 2012 et la norme BBC

- Communication de James Lovelock à la Royal Society

- Communication de la cour des comptes sur la CSPE (juin 2012)

- Communiqué : Nature et limite du foisonnement éolien

- Communiqué de « Sauvons Le Climat » EN

- Communiqué sur les biocarburants

- communqué : « UFC-Que choisir » est-elle manipulée par le lobby du Gaz ?

- Comparaison des scénarios Negatep et Negawatt

- Comparaison des structures énergétiques du Danemark et de la Suède

- Composition atmosphérique et bilan radiatif

- Comprendre la compensation carbone

- Comprendre le chauffage électrique

- Compte rendu de la C.L.I. de Gravelines du 27 octobre 2010

- Compte rendu de la C.L.I. du site de stockage ANDRA de la Manche du 16 décembre 2009

- Compte Rendu de la CLI de Grenoble du 23/12/2011

- Compte rendu du Colloque sur les "Transports propres" organisé par "Ecologie Radicale"

- Compte-rendu de l'AG de la section Bourgogne et Franche-Comté du 21-11-2013

- Compte-rendu de la C.L.I. de Grenoble du 13 mai 2011

- Compte-rendu de la C.L.I. de Grenoble du 29 octobre 2010

- Conclusions de la 6ème université d'été de Sauvons le climat

- Concours étudiants : Règlement

- Conférence "énergies renouvelables" Dijon, 13 mai 2013

- Conférence d'Andrei Nekrassov sur le stockage de l'énergie - Paris - 18 novembre 2010

- Conférence d'Anne FALANGA "Energies de demain" - Dijon - 13 octobre 2011

- Conférence de André Aurengo sur "les faibles doses" - Paris - 9 avril 2009

- Conférence de Bernard Poty - Grenoble - 17 novembre 2009

- Conférence de Bertrand Barré - Grenoble - 5 novembre 2009

- Conférence de Daniel HEUER sur la Génération IV - Grenoble - 11 octobre 2012

- Conférence de Daniel Lincot sur le photovoltaïque - Paris - 29 octobre 2009

- Conférence de François POIZAT : Analyse économique critique du programme éolien français - 11 décembre 2006

- Conférence de François-Marie Bréon - Salives le 24 novembre 2015

- Conférence de Gérard PIERRE sur Frédéric JOLIOT-CURIE - Besançon - 28 septembre 2011

- Conférence de Gérard Pierre sur Frédéric Joliot-Curie - Dijon - 12 janvier 2011

- Conférence de Jacques MASUREL à l'Avere-France

- Conférence de Jean-Philippe Vuillez - Grenoble - 8 février 2011

- Conférence de Jean-Pierre Pervès sur l'éolien - Paris - 18 mai 2009

- Conférence de Pierre Bacher sur "Le facteur 4 en France" - Paris - 13 mars 2009

- Conférence de Pierre SCHMITT et Jean FLUCHERE - Sciences Po - 14 juin 2011

- Conférence du Pr André Aurengo - Grenoble le 17 novembre 2015

- Conférence Environnementale : "Sauvons le Climat" veut faire entendre la voix des scientifiques

- Conférence Glaciations et effet de serre : deux quêtes scientifiques étroitement imbriquées - Grenoble - 12 février 2011

- Conférence SFEN-Grenoble

- Conférence sur la transition énergétique

- Conférence Transition énergétique - Jean Fluchère - Grenoble le 7 mai 2015

- Conférences dans le cadre de la fête de la science à l'ENESAD Dijon

- Conférences SLC / Espace des sciences Pierre Gilles de Gennes

- Confrontation à la réalité : la stratégie perdante de l’énergie verte en Allemagne

- Conseil Européen de l’Énergie : rien d’« historique »

- Conseil Général de Vendée

- Conséquences sanitaires des champs électromagnétiques basse fréquence -

- Conséquences sanitaires des champs électromagnétiques haute fréquence - Effets des rayonnements électromagnétiques radiofréquence, cas de la téléphonie mobile

- Consommation et économies d’énergie, un tour d’horizon

- Contact section régionale

- Contenir le réchauffement climatique, un défi pour nos petits-enfants

- Contenir le réchauffement climatique, un défi pour nos petits-enfants

- Contenu CO2 du chauffage électrique

- Contenu en CO2 du chauffage électrique

- Contribution au débat sur la transition énergétique

- Contribution aux charges de Service Public d’Electricité

- Contribution de « Sauvons le Climat » à la réflexion sur la gestion des pointes de consommation de l’électricité (ateliers DGEC : novembre à février 2010)

- Contribution des éoliennes aux émissions de gaz carbonique

- Contribution possible de l’énergie nucléaire à la limitation du réchauffement climatique

- Contributions de Sauvons le Climat au D.N.T.E.

- Convocation aux Assemblées Générales du 13 avril 2013

- COP 28: Let's Talk Numbers

- COP21 : forces et faiblesses de l’Accord de Paris

- Copenhague

- Copie d’une lettre envoyée au Président d’Arte

- Copie d’une lettre envoyée aux sénateurs et portant sur la loi Grenelle 1

- Corinne Lepage : deux poids, deux mesures…

- Corinne Lepage. Deux poids, deux mesures…

- Cour des Comptes et SLC : mêmes conclusions

- Cours 2008-2009 de Hervé Nifenecker à l'UIAD

- Cours 2009-2010 de Hervé Nifenecker à l'UIAD

- Cours de Jacques Frot : L'avenir mondial du nucléaire

- Coût de la diminution de la part du nucléaire à 50%

- Coût du MWh produit

- Critique du Livre Vert sur l'efficacité énergétique de la Commission Européenne

- Critique du scénario de référence de la DGMEP

- Cycle Daniel Zenatti - Grenoble - 2 au 30 octobre 2008

- Cycle de conférences de Michel Soutif - Grenoble - IV.2010

- De la lumière à la biomasse : la photosynthèse, conférence de Paul Mathis

- De la réhabilitation thermique de l'hâbitat au D.P.E.

- Débat contradictoire "Les énergies en France" - Montbard - 21 mai 2012

- Décarboner l'agriculture

- Décarboner l’industrie : l’exemple d’Industeel France

- Décarboner l’industrie (compte-rendu)

- Décarboner le bâtiment

- Décès de Georges Charpak

- Décès de Pierre Bacher, membre éminent et très apprécié de Sauvons le Climat

- Décision d'arrêt définitif des deux unités de Fessenheim en 2016

- Décision du conseil d'état sur la requête de SLC au sujet de la RT2012

- Déclaration danciens responsables EDF sur le scénario 100% de renouvelables de l'ADEME

- Déconstruction des centrales nucléaires - fiche développement

- Déconstruction des centrales nucléaires - fiche présentation

- Définitions de l’énergie

- Demain, quelle Terre ?

- Demain, quelle Terre ? Dialogue sur l’environnement et la transition énergétique

- Démantèlement du CENG

- Demi-journée sur les énergies sans Carbone

- Dépollution des sols et des eaux par concentration dans des plantes : applications à la chimie et au nucléaire

- Dessalement de l'eau de mer

- Dessalement et réacteurs nucléaires - fiche développement

- Dessalement et réacteurs nucléaires - fiche présentation

- Destin du Nucléaire en France

- Developper l'usage de la chaleur renouvelable

- Développer les énergies renouvelables ?

- Dire la Vérité à Barack Obama – Toute la Vérité

- Dire la Vérité à Barack OBAMA, toute la Vérité - James HANSEN

- Dis, maman, tu sortiras du nucléaire pour moi ?

- Dividing by Four the CO2 Emissions from France in the Energy Sector: the Negatoe Scenario 2017

- Dividing CO2 emissions from energy by four: the Negatep scenario

- Diviser par 4 les rejets de CO2 dus à l’énergie : le scénario Negatep 2010

- Diviser par quatre les rejets de CO2 dus à l’énergie : le scénario Negatep 2012

- Diviser par quatre les rejets de CO2 dus à l’énergie : Le scénario Negatep 2014

- Documents pour les Assemblées Générales du 13 avril 2013

- Doha : au 4ème jour de la conférence

- Doha : ouverture de la conférence climat

- Données essentielles SLC 2006-2010

- Données sur Fukushima

- Drôle de démocratie !

- Du nouveau sur l’effet des faibles doses de rayonnement ?

- Echange de courrier avec Greenpeace Grenoble

- Economies d’énergie - fiche n°1

- Ecotaxe, une autre voie est possible…

- EDF cette entreprise qu’on assassine ! - Jean PINTE

- EDF, AREVA, Alstom et les autres : Où est le problème ?

- Editorial committee

- Effet de serre et climat

- Effet de serre et climat

- Effets de l'irradiation

- Effets des radiations sur l’homme

- Effets sanitaires des faibles doses de rayonnements ionisants

- Einstein et les préjugés

- Ejection de grappe de contrôle : Réponse à "Sortir du nucléaire"

- El Hierro, île à électricité 100% renouvelable ?

- El Hierro, une île à l’électricité 100% renouvelable ?

- Electricité : la concurrence, mais pas le marché ! - Marcel BOITEUX

- Electricité dans l’U.E. : Risque de black-out

- Electricité éolienne en Europe de l’Ouest : intermittence et foisonnement

- Electricité et Effet de Serre

- Electricité et hydrogène

- Electricité et stockage par l'hydrogène

- Electricité photovoltaïque : Halte à la bulle financière ! La stratégie française doit être totalement revue

- Electricity of France. Conférence donnée à l'Ecole Joliot Curie le 15-9-2011 par Hubert Flocard

- Electricity Storage, Reality and Perspectives

- Eléments de réflexion sur l’EPR

- Eléments pour une politique de réduction des émissions de Gaz à Effet de Serre

- Emissions de CO2 : l’Europe récompense les mauvais élèves

- Emplois, énergie et climat

- En quoi l’éolien est-il en retard en France ?

- Energie : l’Allemagne est-elle vraiment le modèle à suivre ?

- Energie : par quoi va-t-on remplacer le pétrole ?

- Energie et changement climatique : éléments de base sur l’énergie au 21e siècle

- Energie et climat : Ce que « Sauvons le Climat » suggère au nouveau gouvernement

- Energie et climat : réussir la transition énergétique

- Energie et Climat, Réponses à une crise annoncée

- Energie et climat: l'Europe reste brouillonne

- Energie et effet de Serre - notes de Henri Prévot

- Energie et Environnement

- Energie et précarité, quelles solutions ? - Précarité énergétique et santé

- Energie solaire : tout revoir

- Energie Solaire et Grenelle : construire une filière nationale et non dilapider 62 milliards d’euros en aides incontrôlées - Patrick JOURDE

- Energies et effet de serre

- Energies marines: France behind, as usual?

- Energies renouvelables Allemagne 2011

- Energies Renouvelables Allemagne 2011 : quels surcoûts pour l’Allemagne et la France ?

- Energy & Climate: France and Europe have made many mistakes

- Environnement et énergie

- Environnement et énergie

- Environnement radioactif naturel et artificiel

- Eolien : une technologie mature, une réalité, des limites

- Eolien et émissions évitées de CO2 : une information grossièrement erronée du « Journal des énergies renouvelables »

- Eolien et système de production d’électricité

- Eoliennes : arrêtons le gaspillage

- Eoliennes en mer : 15 à 20 milliards d'investissements en vue, un contresens économique et environnemental

- EP Tender - comment s'affranchir du plafond de verre de l'autonomie des véhicules électriques

- EPR - fiche développement

- EPR - fiche présentation

- Espagne : données sur la production électrique éolienne

- Essayer de se faire une opinion sur la voiture individuelle à air comprimé - Frédéric LIVET

- Et si la France jouait ses cartes ? - Pierre DELAPORTE

- Et si la France sortait du nucléaire ?

- Et si le GIEC n'existait pas ...

- EU must include nuclear power in its list of sustainable sources

- Europe de l'électricité : propositions de la commission

- Evaluation de la Loi Grenelle I

- Evolution de la politique énergétique allemande

- Exces de leucemies

- expertise technico-économique sur le maintien en fonctionnement de Fessenheim

- Exposé de Gérard PIERRE à l'AG de la SFEN - Dijon le 22 mai 2014

- Exposé de Gérard PIERRE à l'AG de la SFEN - Dijon le 22 mai 2014

- Extension de l'assiette de la CSPE

- External links

- Facéties et Rogatons du professeur Anthelme Triboulet

- Faire de la sureté nucléaire un bien public mondial

- Faits divers au café de la salade verte

- Faut-il mettre 75, 100, 200 … milliards pour soutenir l’électricité verte ?

- Faut-il regretter l’augmentation du prix du pétrole ?

- Faut-il revoir les conditions d’évacuation à la suite d’un accident nucléaire ?

- Faut-il sauver le photovoltaïque ?

- Faut-il vraiment fermer Fessenheim ?

- Fédération Nationale des Associations d'Usagers des Transports

- Fermeture de Fessenheim : communiqué du CCE EDF

- Fessenheim : Lettre des Directeurs de Centrales aux salariés d'EDF

- Fessenheim : Un ancien d’EDF indigné par « Envoyé Spécial »

- Fessenheim et harcèlement moral - Annick WALLER

- Fessenheim Lettre ouverte à M.Rol-Tanguy

- Fessenheim Nuclear Reactor Permanent Shutdown - An Immense Waste for the Climate and for the Country

- Fessenheim: the Second Step in a Disastrous Drift

- Fête de la Science 2015

- Fête de la Science 2015 à Dijon

- Fission nucléaire, réaction en chaîne et criticité

- Fission nucléaire, réaction en chaîne et criticité

- France : Analyse graphique mensuelle par filières de la production électrique (données eCO2mix)

- France : données annuelles par région eCO2mix (site rte-France.com)

- France : données eCO2mix (site rte-France.com)

- France : Outils de dépouillement des données eCO2mix de RTE

- FRANCE : Perspectives énergétiques pour 2050

- France's and Europe's Electricity Supply Security is at Risk

- France's and Europe's Electricity Supply Security is at Risk (short version)

- Frémissements de réalisme ?

- Froid, chauffage, santé

- Fukushima : informations

- Fukushima 30 mois après

- German Electricity and its Negative Prices

- Germany Has Completed Its Nuclear Power Phase Out

- GIEC - Contribution du groupe de travail I au 4ème rapport d'évaluation

- GIEC - Contribution du groupe de travail II au 4ème rapport d'évaluation

- GIEC - Contribution du groupe de travail III au 4ème rapport d'évaluation

- GIEC - Site officiel : IPCC International Panel on Climate Change

- Glaces de l’Antarctique : une mémoire, des passions

- Glaciations et effet de serre : deux quêtes scientifiques étroitement imbriquées

- Grande panne, grandes éoliennes, grands et petits profits

- GRANDE PREMIERE !

- Greenpeace "Face-nuke" un danger pour la démocratie

- Grenelle : le SER chiffre le coût des énergies vertes

- Gros temps sur la planète

- Halte au démarchage éhonté pour le photovoltaïque !

- Halte aux arnaques renouvelables !

- Health Costs of Energy

- Health Costs of the Different Energy Sources

- Health Impacts of the Different Energy Sources (short version)

- Health Impacts of the Different Energy Sources

- Health Impacts of the Different Energy Sources

- Histoire du climat de la terre : implications pour demain

- Histoire du climat depuis l’an mil

- How much can nuclear energy do about global warming ?

- How much can wind reduce the French CO2 emissions?

- How the association works

- How the French electricity grid managed a "normal" month of winter in January 2017

- Il faut un débat public avant de fermer Fessenheim !

- Impact du changement climatique et adaptation de l'agriculture

- Impact du changement climatique sur l'agriculture

- In 2020, France Must not Spoil Its Excellent "Climate Assets"

- Influence de la dissolution de quantités croissantes de CO2 dans l’eau de mer

- Innover pour sauver le climat - Grenoble le 16 juin 2014

- Inspection par l'A.S.N. du réacteur de l'I.L.L. 5 au 7 septembre 2011

- Intermittence des énergies éolienne et solaire : quelles solutions?

- Intermittence et foisonnement de l’électricité éolienne en Europe de l’Ouest

- Intermittent renewable electricity: No stock, no power!

- International group of climate experts questioned President Macron's pledge to shrink nuclear power supply

- Ionel Solomon

- Is a "100% Renewables" Power System Really Feasible?

- Is the French Government Turning a Deaf Ear to Youth Demanding Climate Warming Action?

- Isolation de logements collectifs - Raymond WARLOP

- It Happens Only to Others

- ITER

- ITER à Cadarache

- James Hansen écrit à Barack Obama

- Japon 11 Mars 2011 - Séisme et Tsunami de SENDAI

- Jeremy RIFKIN - La 3ème révolution industrielle

- Join Saving Climate

- Jouer avec les chiffres du climat : une approche par budget carbone

- July 2019 Global Temperature Update

- Jusqu’à quand les gouvernements et leurs conseillers refuseront-ils de faire vraiment face à la réalité du réchauffement climatique?

- Kyoto, climat et commerce de CO2 : fondements juridiques, économiques et stratégiques

- Kyoto, où en est l’Europe ? ou l’Est au secours de l’Ouest

- L'abandon de la taxation du CO2 : une occasion perdue.

- L'accident de Tchernobyl et ses conséquences en France - fiche développement

- L'accident de Tchernobyl et ses conséquences en France - fiche présentation

- L'apprentissage de la "Subvention Durable"

- L'autoroute électrique

- L'avenir énergétique décidé sur un coin de table !

- l'avis de Sauvons Le Climat sur le Livre Blanc sur le financement de la transition écologique

- L'effet de l'accident du Fukushima sur la production et la consommation d'électricité du Japon

- L'effet de l'accident du Fukushima sur la production et la consommation d'électricité du Japon (révision août 2015)

- L'effet de serre, un processus mal nommé

- L'électricité est-elle le vecteur énergie de l'avenir pour la santé publique ?

- L'énergie dans le contrat de gouvernement de l'Allemagne (déc. 2013)

- L'énergie éolienne - fiche développement

- L'énergie éolienne - fiche présentation

- L'énergie éolienne, c'est pour quand ?

- L'énergie solaire - fiche développement

- L'énergie solaire - fiche présentation

- L'énergie, les principaux points clés

- L'énergie, moteur du progrès ?

- L'énergie, moteur du progrès ? - Un livre de Paul Mathis

- L'éolien et la panne du 4 Novembre

- L'équilibre production / consommation d'électricité en France jusqu'en 2030

- l'essentiel du Résumé pour Décideurs du nouveau rapport du GIEC (2013)

- L'essentiel sur l'Association Sauvons le Climat

- L'Europe de l'électricité : une "usine à gaz" ?

- L'évolution de la banquise arctique

- L'évolution du climat. Conférence donnée par Jean Poitou

- L'exemple Belge

- L'hydraulique

- L'hydrogène - fiche développement

- L'hydrogène - fiche présentation

- L'inexorable disparition estivale de la banquise arctique

- L'obligation d'achat joue-t-elle contre les filières renouvelables nationales ?

- L'UFC-Que choisir est-elle manipulée par le lobby du Gaz ?

- L’Académie des Sciences affirme la réalité du rôle actuel de l’homme sur le climat

- L’accident de Fukushima et ses conséquences : faits, explications et commentaires

- L’ADEME a été prudente en ne publiant pas son scénario

- L’affaire Lipowski, une enquête climatiquement incorrecte

- L’air de notre temps, le climat, les hommes et les molécules

- L’air et la ville

- L’analyse scientifique doit avoir la place qui lui revient dans le débat public

- L’analyse scientifique doit avoir la place qui lui revient dans le débat public

- L’artifice du « TaR(T)AM » et de la « CUHN » - François POIZAT

- L’atome hexagonal

- L’avenir climatique

- L’Avenir énergétique mondial au 21ème siècle

- L’avenir énergétique mondial au 21ième siècle

- L’économie des politiques climatiques

- L’effet de serre atmosphérique : plus subtil qu’on ne le croit !

- L’électricité pendant la vague de froid de février 2012 : La Servante et les Danseuses

- L’énergie

- L’énergie : ressources, technologies et environnement

- L’énergie dans le monde

- L’énergie dans le monde : bilan et perspectives

- L’énergie dans le monde en 2011 : Quelles leçons en tirer pour l’avenir ?

- L’énergie de demain : Techniques, environnement et économie

- L’énergie en 21 questions

- L’énergie nucléaire

- L’énergie nucléaire a-t-elle un avenir ?

- L’énergie nucléaire civile dans le cadre des changements climatiques : Rapport à l’Académie

- L’énergie nucléaire. Un atout pour l’avenir

- L’éolien et les émissions de CO2 en Belgique - André BERGER

- L’état actuel et les perspectives techniques des énergies renouvelables

- L’Europe de l’électricité : analyse des propositions de la Commission préalables aux Conseils du mois de mars

- L’Europe de l’électricité : des logiques contradictoires EN

- L’Europe de l’électricité : les propositions de la Commission européenne avant les Conseils du mois de mars

- L’Europe de l’énergie sera-t-elle allemande ?

- L’Europe se remet au charbon

- L’extension de l’assiette de la CSPE

- L’homme est-il responsable du réchauffement climatique : analyse du livre d’André Legendre

- L’homme et le climat

- L’homme face au climat

- L’incident du 9 août 2009 à la centrale de Gravelines

- L’innocence du carbone : l'effet de serre remis en question

- L’innovation et la course à la nouveauté dans la recherche

- L’objectif 3 fois 20, ou la mauvaise façon d’utiliser les Energies Renouvelables

- L’offensive contre le chauffage électrique

- L’offensive contre le chauffage électrique : Petits calculs et grandes magouilles

- L’ozone stratosphérique

- La baisse du prix du pétrole : une occasion perdue ?

- La banquise arctique continue à décroître; elle atteint son deuxième niveau le plus bas

- La biomasse : analyse critique du scénario Negawatt

- La biomasse énergétique

- La biomasse, énergie d’avenir ?

- La candidate et l'EPR

- La catastrophe de Fukushima (diaporama)

- La consommation d’énergie au XXIème siècle

- La contamination radioactive interne

- La crise pétrolière, analyse des mesures d’urgence

- La CSPE : une TVA déguisée et dévoyée - Synthèse

- La CSPE ? Une TVA déguisée. Et dévoyée !

- La Démocratie des Crédules

- La doxa et l'expertise seront-elles conciliables dans la transition énergétique?

- La durée de vie des réacteurs nucléaires - B.GIRAUD & al.

- La fermeture de centrales nucléaires est-elle aussi inéluctable que le prédit la Cour des Comptes ?

- La France doit garder le contrôle de sa politique électrique

- La France exporte de l'électricité vers l'Allemagne !

- La fusion thermonucléaire contrôlée

- La génération IV

- La géothermie

- La Gérondeaucratie - Dominique VIGNON

- La gestion des déchets radioactifs - fiche développement

- La gestion des déchets radioactifs - fiche présentation

- La glace arctique à la fin de l’été 2009 (communiqué du NSIDC)

- La Hausse des prix du Pétrole : une fatalité ou le retour du politique

- La loi sur la transition énergétique devrait avoir un seul objectif : réduire les émissions de gaz à effet de serre au moindre coût

- La loi sur la transition énergétique devrait avoir un seul objectif : réduire les émissions de gaz à effet de serre au moindre coût

- La lutte contre le changement climatique - COP21 : contribution de Sauvons Le Climat

- La lutte contre le changement climatique - COP21 : propositions de Sauvons Le Climat

- La lutte contre le changement climatique COP 22

- La maison écologique

- La Météorologie

- La mort annoncée du premier "smartgrid"

- La part du logement dans la transition énergétique

- La place des biotechnologies en France et en Europe

- La politique allemande de promotion des cellules solaires

- La politique de développement des énergies renouvelables : Analyse du rapport de la Cour des Comptes (juillet 2013)

- La pollution atmosphérique

- La position de la Société Européenne de Physique sur la politique européenne de réduction des émissions de CO2

- La problématique de la production de chaleur dans l'habitat et le tertiaire

- La problématique mondiale de l'énergie

- La production d'électricité photovoltaïque de la France

- La propulsion nucléaire - fiche développement

- La propulsion nucléaire - fiche présentation

- La qualité de l’air : une exigence pour une bonne transition énergétique

- La question des déchets nucléaires

- La radiothérapie

- La recherche nucléaire freine-t-elle le développement des énergies renouvelables ?

- La Réhabilitation du Logement Ancien

- La relance du nucléaire dans le monde

- La RT 2012 devant le Conseil d'Etat

- La RT 2012, Arme antinucléaire ?

- La saga des arrêtés tarifaires de l’éolien - François POIZAT

- La Science au coeur de nos vies

- La section Bourgogne et Franche Comté de Sauvons Le Climat

- La Servante et les Danseuses : L’électricité pendant la vague de froid de Février 2012

- La situation énergétique en France et dans le monde. Quels choix politiques ?

- La situation énergétique en France et dans le monde. Quels choix politiques ?

- La sortie du nucléaire est-elle compatible avec le respect du protocole de Kyoto ? L’exemple de la Belgique

- La stratégie verte de l'Allemagne: un constat d'échec

- La Suède abandonne la sortie du nucléaire

- La suppression du Dakar

- La taxe carbone vue par la mission mandatée par le gouvernement

- La taxe ou les Soviets - Marcel BOITEUX

- La Terre chauffe-t-elle ?

- La transition énergétique : un point de vue

- La transition énergétique allemande

- La transition énergétique est à l'ordre du jour

- La transition énergétique et la production d’électricité : la face cachée de la loi « LTE »

- La troisième révolution énergétique

- La troisième révolution industrielle

- LA VERITE SUR LE NUCLEAIRE Le choix interdit

- La vision béatifique et aéroportée du professeur Anthelme Triboulet

- La voiture électrique est-elle écologique ?

- La Voiture Urbaine Electrique - Denis LINGLIN

- Le "mix électrique" : son évolution peu réaliste dans le scénario ADEME 2030 - 2050

- Le « grand emprunt » et le solaire photovoltaïque : un même poids, deux mesures

- Le « Tournant Energétique » de l'Allemagne n'est pas un modèle à suivre

- Le bois-énergie

- Le bois, énergie renouvelable

- Le captage-stockage du CO2 - fiche développement

- Le captage-stockage du CO2 - fiche présentation

- Le changement climatique

- Le chauffage hybride

- Le chauffage hybride : beaucoup d’atouts dès aujourd’hui et pour demain

- Le Climat : la Terre et les Hommes

- Le climat de la Terre, un passé pour quel avenir ?

- Le Climat et son évolution

- Le climat, toujours parent pauvre des débats sur l'énergie

- Le CO2 joue-t-il un rôle dans le fonctionnement du climat global ? L’opinion d’un amateur passée au crible

- Le CO2 ne menace pas que le climat

- Le Collectif « Sauvons le Climat » lance un Appel aux écologistes de raison

- Le Combat est une fête

- Le Comité de Parrainage

- Le Comité Editorial

- Le Comité Editorial

- Le Conseil d'Administration

- Le Conseil Scientifique

- Le Credo antinucléaire Pour ou contre ?

- Le Cs137 est-il dangereux pour le coeur ? - Hervé NIFENECKER

- Le débat public sur CIGEO

- Le débat sur l'EPR est-il mort-né ?

- Le devenir des déchets très radioactifs et à très longue durée

- Le devenir du climat : pourquoi agir ? Université d'été 2014 de Sauvons Le Climat

- Le futur énergétique de l’Allemagne. Comparaison avec le scénario France Négatep

- Le futur énergétique en France ?

- Le G7 prend conscience de la nécessité de réduire nos émissions de Gaz à Effet de Serre, mais abandonne, tout en affirmant le contraire, l’objectif de la limitation à 2 degrés du réchauffement climatique

- Le gaz, énergie propre et sûre ?

- Le GIEC expliqué par Michel Petit

- Le Gouvernement sacrifie la recherche publique mais arrose le SER

- Le Gouvernement sacrifie la recherche publique mais arrose le SER

- Le Grenelle de l’Environnement : et après ?

- Le Groupe Intergouvernemental sur le Climat (GIEC)

- Le livre blanc sur le financement de la transition écologique : peut-il être utile ?

- Le Livre Vert de la Commission Européenne sur l'efficacté énergétique et le plan d'action du G8

- Le Manifeste de Sauvons le Climat

- Le mécanisme de contribution aux Charges de Service Public d‟Electricité

- Le Méthane et le destin de la terre

- Le méthane, une bombe à retardement pour le réchauffement global ?

- Le mix électrique 100% ENR de l'ADEME

- Le Monde préfère la sortie du nucléaire à la réduction des émissions de CO2

- Le mythe climatique

- Le nouveau paquet énergie climat de la Commission européenne : un monument à recentrer sur les vraies priorités !

- Le nucléaire : une solution durable

- Le nucléaire au service de la conservation des aliments par ionisation - fiche développement

- Le nucléaire au service de la conservation des aliments par ionisation - fiche présentation

- Le Nucléaire contribue-t-il à l’indépendance énergétique ?

- Le nucléaire et la planète Dix clés pour comprendre

- Le nucléaire et ses accidents - Marcel BOITEUX

- Le nucléaire expliqué par des physiciens

- Le nucléaire expliqué par des physiciens

- Le nucléaire ne comporte-t-il pas au moins autant de dangers que les combustibles fossiles ?

- Le nucléaire,avenir de l’écologie ?

- Le Nucléaire: un choix raisonnable?

- Le paradoxe des faibles doses

- Le pays de Kyoto tourne le dos à Kyoto

- Le photovoltaïque de nuit...

- Le pic pétrolier et l'Europe, une situation d'urgence

- Le Plein s’il vous plait

- Le plutonium

- Le polonium 210

- Le principe de precaution (2)

- Le prix du pétrole et l'EPR à Flamanville

- Le problème de l'intermittence des renouvelables : Eolien et Solaire

- Le projet de loi sur la nouvelle organisation du marché de l’électricité (NOME) : risques sérieux d’augmentation des émissions de gaz carbonique

- Le Projet Socialiste et le Réchauffement Climatique

- Le radium

- Le radon - fiche développement

- Le radon - fiche présentation

- Le Radon de l’environnement à l’homme

- Le rapport de la Cour des Comptes démontre la rentabilité de la filière nucléaire

- Le rapport de la Cour des Comptes sur la politique de développement des énergies renouvelables : Une contribution essentielle au débat sur la transition énergétique

- Le réacteur Jules Horowitz - fiche développement

- Le réacteur Jules Horowitz - fiche présentation

- Le réchauffement climatique : fiction ou réalité ?

- Le réchauffement climatique : mythe ou réalité ?

- Le réchauffement climatique (par Jean Poitou)

- Le réchauffement climatique est en route, ici.

- Le réchauffement climatique: un enjeu politique

- Le Réchauffement du Climat au XXIe Siècle : Causes et Conséquences

- Le réchauffement du climat fiction ou réalité ? (Compte-rendu)

- Le réchauffement global se poursuit - 2010 est l’année la plus chaude jamais enregistrée

- Le renouvelable : une autre approche - Patrick JOURDE

- Le réseau électrique

- Le retraitement du combustible nucléaire usé

- Le risque terroriste

- Le risque terroriste d'une "bombe sale"

- Le scénario ADEME est-il crédible ?

- Le scénario Negatep

- Le scénario Négatep de Sauvons le climat

- Le scénario Negatep présenté dans la "Revue du Projet" du P.C.F.

- Le SER mène le bal....

- Le solaire électrique

- Le solaire fait son apparition dans la campagne présidentielle

- Le solaire photovoltaïque au service du développement

- Le solaire thermique

- Le solaire thermique à concentration (CSP)

- Le solaire thermodynamique

- Le transport des matières radioactives - fiche développement

- Le transport des matières radioactives - fiche présentation

- Le transport routier décarboné : Conférence de Jacques Masurel - Dijon le 20 février 2014

- Le transport routier décarboné : Conférence de Jacques Masurel - Dijon le 20 février 2014

- Le vent pourrait-il remplacer le nucléaire ?

- Le vent souffle où [et quand] il veut

- Le Voyage de l’Uranium dans la Nature

- Le vrai choc pétrolier reste à venir pour l’Europe !

- Legal notice

- Les ambiguïtes de la concurrence

- Les analyses de Sauvons le Climat confortées par le rapport de la Cour des Comptes sur les coûts de la filière nucléaire

- Les apports de la science et de la technologie au développement durable

- Les batteries

- Les Biocarburants

- Les biocarburants, situation et perspectives

- Les bons comptes …

- Les causes du cancer en France

- Les caves se rebiffent

- Les CEE (certificats d’économie d’énergie) et la réduction d’émission de gaz à effet de serre

- Les centrales les plus polluantes d’Europe selon WWF (extraits d’une dépêche AFP du 10/05/2007)

- Les Certificats d'Economie d'Energie (C.E.E.)

- Les choix énergétiques et leurs conséquences

- Les chroniques radio d'Hervé NIFENECKER

- Les chroniques sur l'énergie et le climat du Professeur Gérard PIERRE (et d'autres...)

- Les cinq points faibles majeurs du scénario ADEME

- Les combustibles fossiles (charbon, pétrole, gaz naturel…)

- Les Commissions Locales d'Information

- Les conséquences sanitaires de l'exploitation des gaz de schistes

- Les dangers du charbon

- Les déchets nucléaires : Un dossier scientifique

- Les déchets radioactifs : une raison pour s’opposer au nucléaire ?

- Les décisions de l’Autorité de Sûreté Nucléaire après Fukushima

- Les différentes sources d'énergie. Fiches rédigées par le Conseil scientifique de Sauvons Le Climat

- Les ECS au sein du parc nucléaire EDF - 11 octobre 2011

- Les effets sanitaires des faibles doses de radiation

- Les électricités renouvelables solaire et éolienne : l'exemple allemand

- Les émissions de CO2 du Danemark et de la Suède : une comparaison instructive

- Les énergies : comprendre les enjeux - Nouveau livre de Paul Mathis

- Les énergies décarbonées

- Les énergies en Inde

- Les énergies renouvelables État des lieux et perspectives

- Les énergies renouvelables - Conférence de Gérard PIERRE et Christophe GALOPIN

- Les énergies renouvelables : un tour d’horizon

- Les énergies renouvelables (livre de Acket et Vaillant)

- Les énergies renouvelables dans la transition énergétique : on peut faire beaucoup mieux pour beaucoup moins cher (par Hervé NIFENECKER)

- Les énergies renouvelables, l'énergie nucléaire et Galilée : Les scientifiques n’ont-ils pas le devoir de dénoncer les idées fausses?

- Les énergies, comprendre les enjeux

- Les éoliennes

- Les éoliennes manquent souvent de vent, Greenpeace jamais de souffle

- LES EOLIENNES, DU VENT ?

- Les éoliennes, du vent ? (de Marcel Boiteux)

- Les faibles doses

- Les fiches énergies du Conseil Scientifique de SLC

- Les fondamentaux de Negatep

- Les gaz de schistes : rejet justifié ou diabolisation ?

- Les impacts sanitaires du réchauffement climatique et de l'activité humaine

- Les logiques contradictoires de l’Europe de l’électricité

- Les marchands de doute

- Les négociations à venir sur les changements climatiques. Bilan et Perspectives

- Les Nouvelles technologies de l’énergie

- Les outils de simulation

- Les paradoxes d’Hiroshima et Nagasaki

- Les perspectives de l’énergie solaire en France

- Les points forts du "résumé pour décideurs" du rapport sur les bases scientifiques du réchauffement

- Les Pompes à chaleur

- Les pompes à chaleur

- Les possibilités d’entreposage à long terme des combustibles nucléaires irradiés

- Les prêcheurs de l’Apocalypse Pour en finir avec les délires écologiques et sanitaires

- Les questions d'actualité du Professeur Gérard PIERRE et de ses invités

- Les rayons X et la médecine

- Les réacteurs nucléaires peuvent faire face aux variations de la demande

- Les réserves d’Uranium seront-elles suffisantes ?

- Les risques de la pollution atmosphérique

- Les risques de la pollution atmosphérique pour la mortalité prématurée. Comparaison avec ceux du tabac et ceux de la radioactivité.

- Les risques de prolifération de l’arme nucléaire

- Les tarifs déréglementés seront-ils bons pour le climat? Le « rapport Champsaur » sur l’électricité

- Les trains du charbon

- Les Verts au charbon, plein gaz ! - Jacques TREINER

- Letter to the European MP on the Climate Energy package

- Lettre à François Hollande, nouveau Président de la République

- Lettre à Philippe Martin : concertation

- Lettre à Ségolène Royal (15 avril 2014)

- Lettre ouverte à ceux qui nous informent

- Lettre ouverte à Hervé Kempf

- Lettre ouverte à la FNE

- Lettre ouverte à Madame Cécile Duflot

- Lettre ouverte à Michel de Pracontal

- Lettre ouverte à Nicolas Hulot

- Lettre ouverte à Nicolas Hulot

- Lettre ouverte à Ségolène Royal

- Lettre ouverte au Ministre de l’Ecologie, du Développement Durable et de l’Energie

- Lettre ouverte au Président de la Commission Européenne

- Lettre ouverte au Président de la République

- Lettre ouverte aux candidats à la primaire d'E.E.L.V.

- Lettre ouverte aux dirigeants de nos grands électriciens

- Lettre ouverte aux responsables du PS et de EELV

- Lettre ouverte aux responsables du PS et de EELV

- Limites de l'intégration des productions d'électricité intermittente (Etude)

- Livre : A petites doses, de Jean-Claude ARTUS

- Livre : La biomasse, énergie d’avenir ?

- Lucky German Electricity Consumers

- Mais quelle mouche pique Claude Allègre ?

- Mais qui est donc "GP" ?

- Maitrise des émissions nécessaire pour limiter le changement climatique anthropique

- Maîtriser le nucléaire

- Mauvais Climat (un livre de Jacques Masurel)

- Mauvais Climat. Du froid sur le réchauffement

- Médecine nucléaire

- Merci Nicolas

- Mes points sur les i

- Message aux éoliens de bonne foi

- Mesures gouvernementales en faveur de la voiture électrique : un grand progrès

- Mix énergétique : quelle place pour le nucléaire ?

- Mobilité fiche n°1: Une voiture hybride "rechargeable"

- Mobilité fiche n°2 : Transport par câble Vizille-Grenoble

- Moins de CO2 pour pas trop cher

- Mondial de l’Automobile : une offre de véhicules propres en forte croissance, mais attention aux publicités peu claires et aux alléchantes performances affichées !...

- Mortalité et émissions de gaz à effet de serre évitées par les centrales nucléaires historiques et en projet

- Mouvement National de Lutte pour l'Environnement

- Munitions à uranium appauvri - fiche développement

- Munitions à uranium appauvri - fiche présentation

- Natural Gas Treated as "Clean Energy" by the European Union, LREM and the Former President of WWF France

- Nature et limite du foisonnement éolien

- Negatep 2014 : Réduire les rejets de gaz carbonique. Oui, mais à quel coût ?

- NEGATEP de SLC : l’éco-cohérence des choix énergétiques

- Négawatt / Négatep, le coût de la transition énergétique

- Négawatt, un scénario peu réaliste et un pari risqué

- News Brief: Should France Do Without Nuclear Power for Fear of an Accident?

- Newsbrief : Is a "100% Renewables" Power System Really Feasible?

- Newsbrief : Massive methane leaks that must be prevented

- Newsbrief: Climate: a weak France sacrificing its interests within a weak Europe

- Niches fiscales

- No credible scenario without nuclear

- Non, l'EPR n'est pas le réacteur le plus dangereux du monde

- Note sur les STEP

- Notes de lecture sur le projet de PPE

- Nourriture ou biocarburants : faudra-t-il choisir ?

- Nouveau : Livre de Claire Kerboul "L'urgence du nucléaire durable"

- Nucléaire : Questions/Réponses

- Nucléaire = Economies

- Nucléaire et changement climatique

- Nucléaire et renouvelables sont ils vraiment complémentaires ?

- Nucléaire et suivi de réseau

- Nucléaire, Energie et Environnement : Eléments de discussion

- Nuclear Excluded from EU Sustainable Finance? An Aberration!

- Nuclear Power reduced to 50 %: Less Security, More CO2

- Nuclear Power: The Low-Carbon Energy of the Future

- Obligation d’achat, prix administré : l'opacité du marché de l'électricité

- Oh ! Ministres et conseillers intègres : quand direz vous la vérité à Monsieur le Président de la République ?

- Opacite éolienne

- OPECST - Rapport sur la sécurité nucléaire

- Optimiser le déploiement des énergies renouvelables

- Organisation mise en place pour les entreprises prestataires de la maintenance du parc nucléaire français

- Oser le nucléaire pour trouver la solution au problème climatique !

- Ouf ! Encore du pétrole pour près d’un siècle… (et tant pis pour le climat !)

- Our mission

- Pandora's promise

- PANDORA’S PROMISE

- Parlons Climat en 30 questions

- Participation de Sauvons le Climat à la Commission Energie 2050

- Pay your membership fee

- Pays de la Loire : Analyse graphique mensuelle par filières de la production électrique (données eCO2mix)

- Performance énergétique des bâtiments : résumé du rapport de l'OPECST du 2 décembre 2009 et commentaires

- Personnalités signataires du Manifeste

- Perspectives de l’énergie nucléaire

- Perspectives énergétiques pour 2050

- Pertes énergétiques du schéma « Power to gas + Gas to power »

- Petit pense-bête à l’intention de ceux qui croient en l’avenir de l’industrie nucléaire française et de ceux qui n’y croient pas

- Pétrole et transports : effets sanitaires dus à la pollution atmosphérique des différents modes de transport

- Peut-on faire crédit à l’ADEME ?

- Peut-on sortir du nucléaire ? Après Fukushima, les scénarios énergétiques de 2050

- Photovoltaïque - fiche n°1

- Photovoltaïque - fiche n°2

- Photovoltaïque - fiche n°2b

- Photovoltaïque - fiche n°3

- Photovoltaïque : aussi bien pour, au minimum, cinq fois moins cher

- Photovoltaïque : lettre aux députés

- Photovoltaïque : oh, la belle bulle ...

- Photovoltaïque : réorienter les aides. Aussi bien pour 10 fois moins cher

- Physique d’un site géologique de stockage de déchets nucléaires

- Place du charbon en Europe

- Plaquette programme SLC : Comment (vraiment) réduire les émissions de gaz à effet de serre

- PLATOV (de G.P.)

- Point de vue : EU Taxonomy for Sustainable Financing: the need to reform the European electricity system

- Poitou-Charentes : Analyse graphique mensuelle par filières de la production électrique (données eCO2mix)

- Polémiques autour de Tchernobyl

- Politique de santé et Principe de précaution : Quo Vadis ?

- Politique énergie-climat : La Cour des Comptes et Sauvons Le Climat aboutissent aux mêmes conclusions

- Politique énergie-climat : la Cour des Comptes prend des positions très proches de celles que défend Sauvons Le Climat

- Politiques européennes après Copenhague

- Politiques européennes de l'énergie après Copenhague - Grenoble - 25 janvier 2010

- Pompe à chaleur - fiche n°1

- Pompe à chaleur - fiche n°2

- Pompe à chaleur - fiche n°3

- Pompe à chaleur - fiche n°4

- Pompe à chaleur - fiche n°5

- Pompe à chaleur - fiche n°6

- Position de la Société Européenne de Physique sur l'option nucléaire

- Position de SLC sur l’EPR

- Position de SLC sur la gestion des déchets nucléaires (débat public)

- Pour enrichir vos vacances

- Pour une gestion durable des déchets nucléaires

- Pourquoi des économies d’énergie ? - Jacques FROT

- Pourquoi le nucléaire

- Pourquoi le scénario électrique de Greenpeace n'est pas réaliste...

- Pourquoi les fiches ARCEA - GASN ?

- Pourquoi Sauvons Le Climat soutient-il le nucléaire ?

- PPH ?

- Prééquipement des bâtiments

- Préparons aujourd'hui les énergies de demain, conférence d'Anne FALANGA - 13 octobre 2011

- Présentation de James Hansen à Paris le 3-12-2015

- Présentation de l'article d'Henri Prévot : « Qui ne veut pas d'une augmentation de la capacité nucléaire ? Des convergences remarquables »

- Presentation note : Nuclear Power reduced to 50 %: Less Security, More CO2

- Présentation résumée du rapport "vecteurs d'énergie"

- Principe de précaution

- Problème pour la cuve de l'EPR ?

- Procès Verbal de l'Assemblée Générale Extraordinaire du 13 avril 2013

- Procès Verbal de l'Assemblée Générale Ordinaire du 13 avril 2013

- Procès Verbal du conseil d'administration du 13 avril 2013

- Procès verbal du conseil d'administration du 8-2-2014

- Procès-verbal de l'Assemblée Générale du 31 janvier 2015

- Procès-verbal de l'Assemblée générale du 8-2-2014

- procès-verbal de l'Assemblée générale ordinaire du 6 février 2016

- procès-verbal du conseil d'administration du 31 janvier 2015

- Production d’énergie et réchauffement climatique

- Production éolienne et température pendant l'hiver 2010-2011

- Projet d’arrêté relatif à la programmation pluriannuelle de l’énergie 2018/2023 (PPE)

- Projet de loi NOME

- Promesses de la voiture électrique - Frédéric LIVET

- Promesses et limites des énergies renouvelables

- Propos sur Tchernobyl

- Proposition de directive du parlement européen sur la promotion des sources renouvelables

- Proposition de résolution sur les sciences et le progrès dans la République

- Propositions de Sauvons le Climat au Grenelle de l'Environnement

- Propositions pour la loi Grenelle 1

- Propositions pour un programme énergétique et écologique

- Propositions pour une révision de la politique énergétique de la France

- Prospectives énergétiques à l’horizon 2100 Données, contraintes et scénarios

- Prospects for CO2 capture and storage

- Qu'est-ce que la biomasse ? - fiche développement

- Qu'est-ce que la biomasse ? - fiche présentation

- Qu’espérer de grandes liaisons transfrontalières sous-marines ? A quel coût ?

- Qu’est ce que l’effet de serre ?

- Que faire de l’éolien ?

- Que faire de la rente nucléaire ?

- Que penser des arguments des climato-sceptiques ?

- Que peut-on attendre de l’éolien ?

- Quel avenir pour les énergies fossiles ?

- Quel coût pour la retraite du nucléaire ?

- Quel coût pour les voitures propres ?

- Quel rôle pour le bâtiment dans la transition énergétique en France ?

- Quel système électrique en 2050 pour la France ?

- Quel système électrique pour la France en 2050 ?

- Quelle énergie pour demain ?

- Quelle énergie pour demain ? fiche développement

- Quelle énergie pour demain ? fiche présentation

- Quelle énergie pour le 21ème siècle ? Intervention de Gérard PIERRE à l'université d'été 2011 du P.C.F

- Quelle mise en oeuvre de la transition énergétique ?

- Quelle pagaille !

- Quelles Energies pour Demain ?

- Quelles énergies pour demain ?

- Quelles perspectives énergétiques pour l'Europe ?

- Quelques éléments de compréhension de l’accident d’éjection de grappe dans l’EPR

- Quelques éléments sur le cycle de l’hydrogène - Frédéric LIVET

- Quelques réflexions concernant l'évaluation du panachage des énergies

- Quels rôles pour l’énergie nucléaire

- Questionnaire aux candidats à l'élection présidentielle

- Questions autour du chauffage bois

- Questions durables

- Qui a rédigé le rapport du Groupe 3 du GIEC ?

- Qui empochera la rente nucléaire ?

- Qui ne veut pas d’une augmentation de la capacité nucléaire ? Des convergences remarquables

- Qui paiera pour le déploiement des énergies vertes?

- Radioactive Waste Management in France

- Rapport de l'Académie des technologies "vecteurs d'énergie"

- Rapport de synthèse de l’ANDRA 2005

- Rapport financier 2006

- Rapport financier 2007

- Rapport financier 2008

- Rapport financier 2009

- Rapport financier 2010

- Rapport financier 2011

- Rapport financier 2012

- Rapport financier 2013

- Rapport financier 2014

- Rapport moral 2006

- Rapport moral 2007

- Rapport moral 2008

- Rapport moral 2009

- Rapport moral 2010

- Rapport moral 2011

- Rapport moral 2012

- Rapport moral 2013

- Rapport moral 2014

- Rapport Poignant Sido : Fin des travaux de la DGEC sur la maitrise des pointes électriques

- Ratification de l'Accord de Paris sur le climat : promesses déjà oubliées ?

- Réchauffement climatique : La Commission Européenne va-t-elle choisir l’impuissance ? - Hervé NIFENECKER

- Réchauffement climatique : ne pas se tromper de méthode

- Réchauffement climatique et effet de serre

- Réchauffement Climatique et Energies

- Réchauffement du climat : il faut agir sans attendre

- Recherche scientifique, choix énergétiques et opinion publique - Réchauffement climatique et perception des énergies

- Records de production éolienne : Il faudra bien finir par penser au stockage !

- Réduction des émissions de CO2 et inégalités sociales - Hervé NIFENECKER

- Réduire la consommation de pétrole dans les transports

- Réflexions sur l'ouverture du capital d'EDF

- Réflexions sur la biomasse énergétique

- Réflexions sur le Débat Public sur l’EPR

- Réflexions sur le Débat Public sur la Gestion des Déchets Radioactifs

- Réflexions sur le livre vert de l'UE : "Une stratégie énergétique pour l´Europe"

- Réflexions sur les aspects énergétiques de l’accord EELV / PS

- Réflexions sur les débats publics sur l'EPR et les déchets radioactifs

- Réforme du Conseil Economique et Social

- Regards de Sauvons le Climat sur les rapports des sept Groupes de Travail du Débat National sur la Transition Energétique

- Regards de SLC sur les rapports des 7 Groupes de Travail du Débat National sur la Transition Energétique (Etude)

- Regards sur la nouvelle politique énergétique allemande

- Regards sur la politique allemande de l'énergie

- Regards sur la politique allemande de l'énergie dans son contexte européen

- Regards sur la transition énergétique allemande : un double pari

- Règlement intérieur 2010

- Règlement intérieur 2016

- Rejets de CO2 en augmentation ? Le scénario énergétique de référence de la DGEMP pour 2030

- Relation entre production éolienne et température sur la période de Novembre 2010 à Février 2011

- Remarques à propos de la « Contribution Climat et Energie »

- Remarques de Sauvons le Climat sur le projet de loi sur la transition énergétique [1]

- Remise à l'herbe du réacteur Siloé

- Renouvellement des concessions hydroélectriques en concurrence

- Renouvellement du parc français de réacteurs nucléaires

- Renouvellement du parc nucléaire français

- Répartition de l’effort de réduction des émissions de GES entre les États européens

- Réponse à Eva Joly

- Réponse de l'IED au point de vue de J.L. Basdevant : « Pourquoi Fessenheim doit être stoppée ? »

- Réponse à "Climat - Comprendre ce qu’on ne vous dit pas"

- Réponse à l’interview de J.L. Basdevant : « Pourquoi il faut stopper la centrale nucléaire de Fessenheim ?»

- Réponse à R.Giraudon

- Réponse aux climato-sceptiques

- Réponse de Sauvons Le Climat à la consultation lancée par le ministre de l’écologie, du développement durable et de l’énergie sur l’évolution des mécanismes de soutien aux installations sous obligation d’achat

- Réponses aux arguments de ceux qui doutent de la réalité d'un changement climatique anthropique

- Réponses des candidats à l'Appel de Sauvons le Climat

- Réponses des candidats à la Présidentielle à la CFE-CGC Energies

- Réponses des candidats au questionnaire SLC

- Report of General Assembly held on 2017-01-28

- Représentativité des associations

- Réserves de Lithium

- Résultats du concours étudiant

- Résumé critique d’une étude du RWI

- Résumé et commentaires de l’article de Nature sur "Electricity without carbon"

- Résumé pour décideurs du rapport du GIEC

- Retombées de Tchernobyl en France

- Réunion du Conseil Européen sur l'énergie

- Réussir la transition énergétique

- Rhône-Alpes et l’avenir de l’énergie hydroélectrique

- Risque sismique pour les Installations Nucléaires de Base

- Riziculture et méthane - Paul MATHIS

- Rôle de l’éolien dans la panne du 4 novembre

- Saga solaire (suite) …

- Sauvons la planète (BD pour les jeunes)

- Sauvons Le Climat auditionné au Sénat sur la LTE

- Sauvons le Climat demande que les auteurs de menaces de mort contre des élus soient activement recherchés et poursuivis.

- Sauvons Le Climat s’incline devant Maurice Tubiana

- Scenario Negatoe 2017 (short version)

- Scientific committee

- SDN dénonce la recherche de la meilleure sûreté possible pour les réacteurs nucléaires !

- Sélection des ouvrages présentés à l'Université d'été 2013

- Selon l’Association Européenne de l’Energie Eolienne, le développement européen de l’éolien requiert la réalisation d’un grand réseau Très Haute Tension

- Should France Do Without Nuclear Power Because of the Waste Issue?

- Should France Do Without Nuclear Power, Considering it an Energy of the Past?

- Should We Do Without Nuclear Power for Fear of an Accident?

- Simulation et dissuasion nucléaire - fiche développement

- Simulation et dissuasion nucléaire - fiche présentation

- Sites consacrés au Climat

- Sites consacrés aux Transports

- Sites généralistes

- Sites institutionnels

- Situation énergétique de la Suède

- Situation ubuesque en Europe : électricité à prix négatifs et chute des investissements !

- SLC appelle à participer à la

- SLC appelle de ses voeux la tenue d'un Grenelle de l'énergie

- SLC Booklet: Climate Warming: Good questions and true answers

- SLC Contribution to the National Debate on the Energy Policy